Special processing (Both AP and NP)

Durability

Hard type

Hardness HRC68

Higher durability

DLC coating

Hardness HV1200

Greater durability by combining with hard type

Titanium coating

Hardness HV1800

Improve durability by Combining with hard type

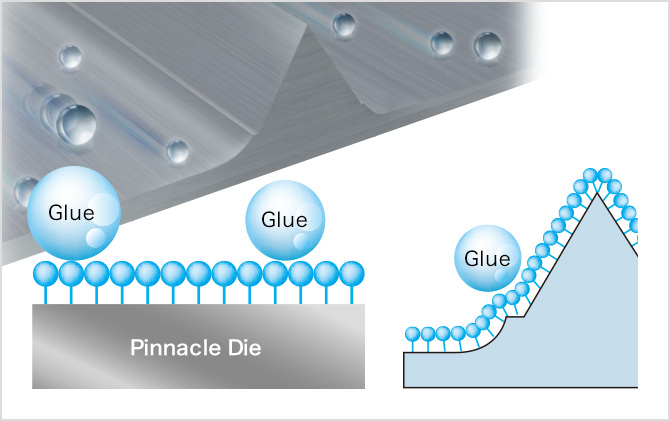

Coating against glue

TS coating (measures against glue)

Super thin filmy non-adhesive coating (monomolecular bond)

Alleviate adhesion of glue and ink

Easy cleaning

Others

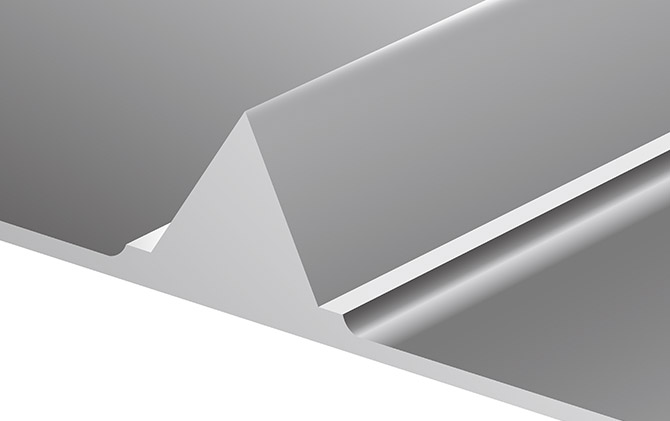

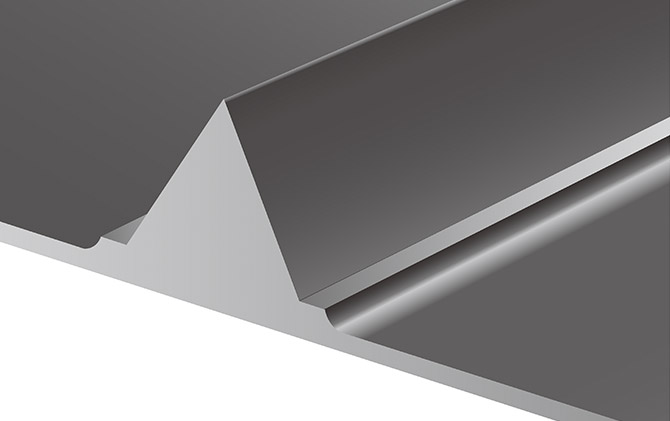

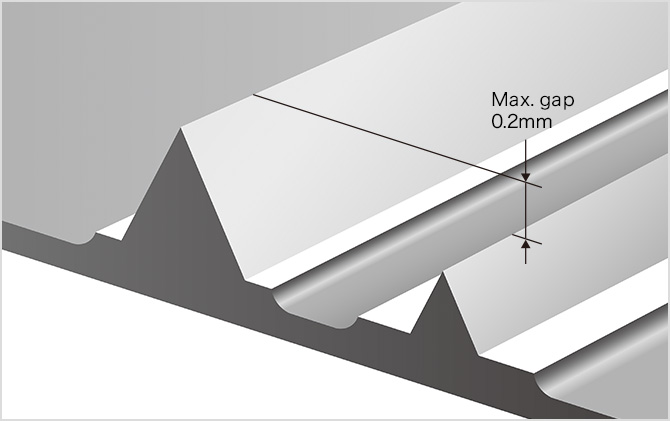

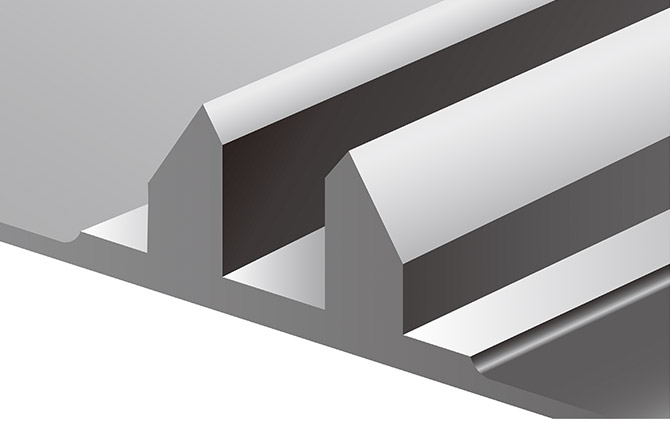

Different height edges

Combination of full cutting and half cutting

Max. gap 0.2mm

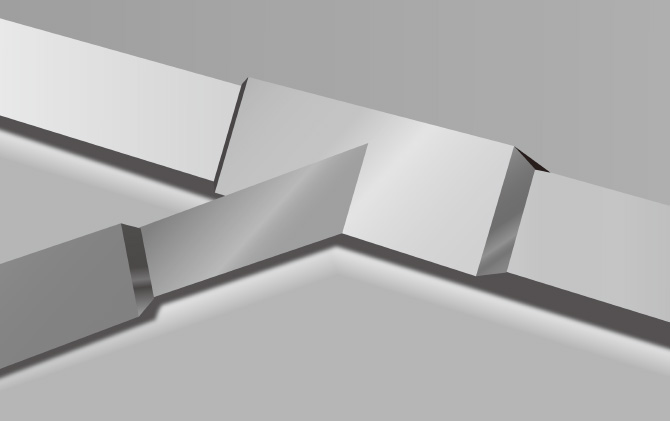

T-Shaped different height edge

Available at T-shaped parts

Different height perforation

Gap differs depending on material

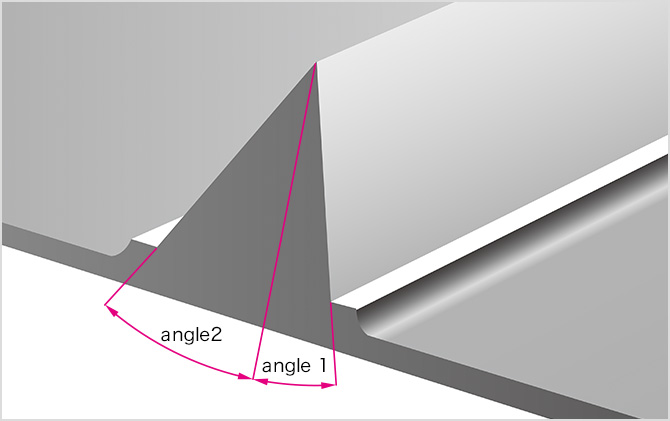

Side edge

Low cutting resistance

Side-open edge (SOE)

Wire-processed side edge

Irregular angles edge

Possible to combine five different angles (15°, 20°, 25°, 30°and 40°)

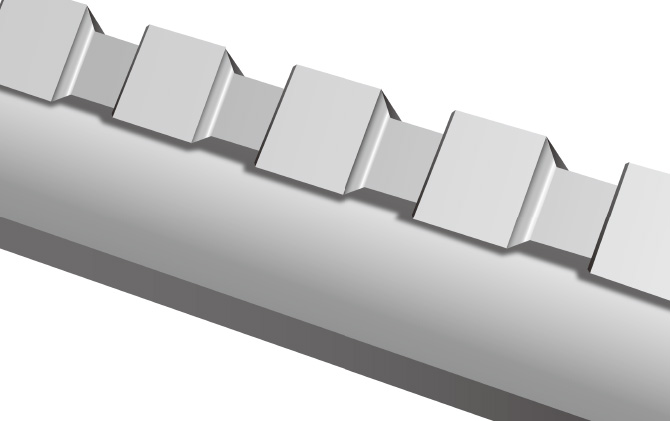

Micro perforation

Available 4 types of pitches

Cut 0.20 x uncut 0.15mm

Cut 0.28 x uncut 0.23mm

Cut 0.30 x uncut 0.20mm

Cut 0.35 x uncut 0.15mm

Pitch depth 0.25mm

*Consult us for pitches other than the above.

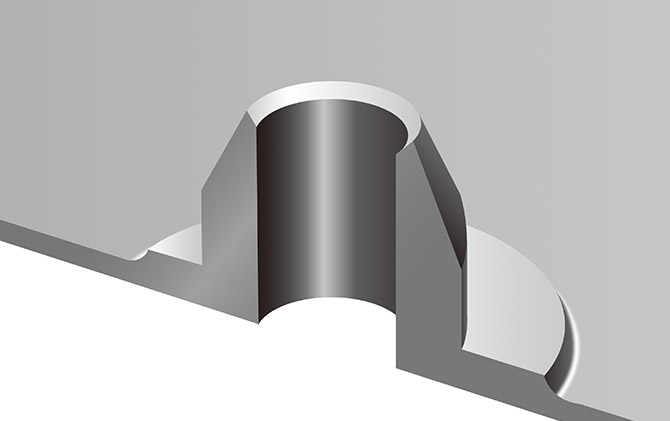

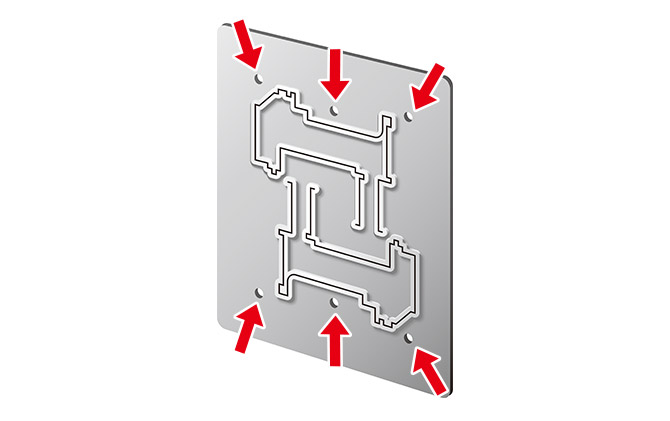

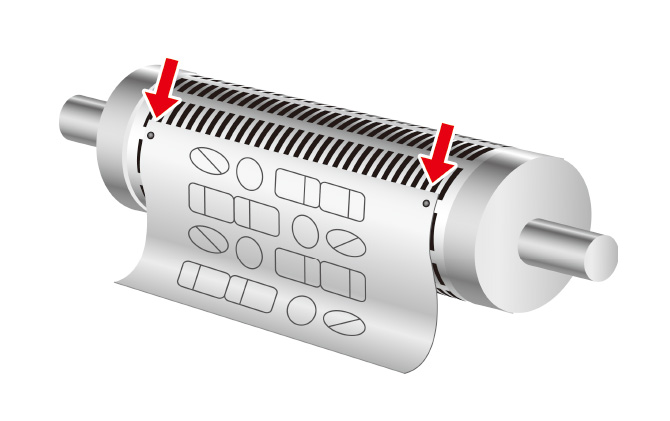

Base-through hole

Diameter 2mm or more

Indispensable for pattern matching and secondary process

Positioning pin

Wire hole processing

Not only circles, but also various shapes

Specifications may be changed without prior notice.

Download brochure

- Flexible Pinnacle Die brochure

- PDF : 67.3MB

- Flexible Pinnacle Die order sheet

- PDF : 197KB